Are you looking to find out detailed information on factors leading to a broken supply chain and ways to fix it? In this article, Hospaccx Healthcare Consultancy has mapped all on major aspects of Hospital Disaster Preparedness.

INTRODUCTION

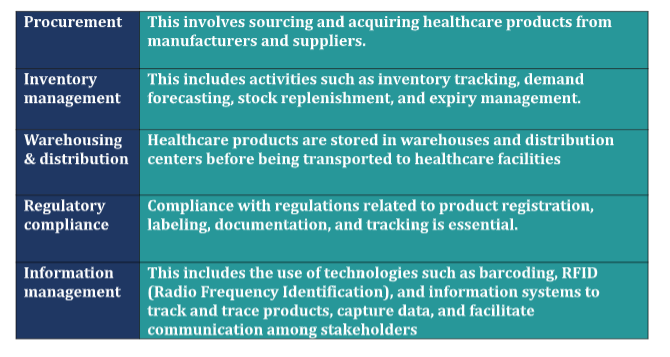

The healthcare supply chain refers to the complex network of activities, processes, and resources involved in the procurement, storage, and distribution of healthcare products, equipment, and services. It includes the movement of drugs, equipment, information, and medical supplies from producers and suppliers to healthcare facilities like hospitals, clinics, and pharmacies.

The availability of important healthcare goods and services when and when they are required is crucially dependent on the healthcare supply chain. Numerous parties are involved, including producers, retailers, wholesalers, medical facilities, regulatory bodies, and logistical companies. These parties cooperate to ensure the prompt and effective delivery of medical supplies while upholding standards for quality, safety, and regulatory compliance.

A crucial part of the healthcare sector, the healthcare supply chain is currently dealing with major difficulties that have shown its underlying fragility. The flow of medical supplies, equipment, and services from suppliers to healthcare facilities has been hampered and disturbed, which has led to shortages, inefficiencies, and subpar patient care. This urgent matter necessitates prompt notice and corrective action.

KEY COMPONENTS AND PROCESSES OF THE SUPPLY CHAIN

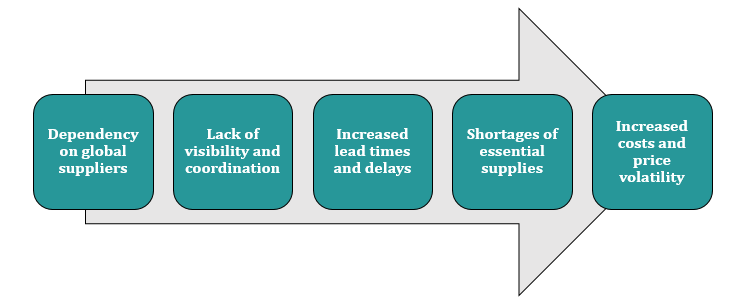

REASONS BEHIND BROKEN SUPPLY CHAIN

The healthcare facility supply chain has been under significant strain and has faced challenges that have contributed to its perceived brokenness. Here are some reasons why the healthcare facility supply chain may be considered broken:

- Lack of coordination and visibility: The healthcare supply chain encompasses a wide range of parties, including producers, retailers, hospitals, and regulatory organisations. These various organisations frequently lack communication and visibility, which causes inefficiencies and delays in the supply chain. This may make it challenging to effectively estimate and meet demand.

a.Gaps in communication:

- A successful supply chain depends on effective communication. Manufacturers, distributors, healthcare facilities, and regulatory authorities frequently lack effective communication routes with one another in healthcare supply chains.

- In crucial procedures like order placement, shipping tracking, and inventory management, this may result in delays and misunderstandings.

- It can be difficult to respond quickly to changes in demand or deal with supply chain interruptions when communication is ineffective since it can lead to inaccurate or delayed information flow.

b.Limited visibility:

- Lack of visibility refers to the inability to track and monitor the movement of products and information throughout the supply chain.

- Without a comprehensive view of inventory levels, shipment status, and demand patterns, it becomes difficult for stakeholders to make informed decisions. Limited visibility can result in overstocking or understocking of essential supplies, leading to either wastage or shortages.

- It also hampers the ability to identify bottlenecks or inefficiencies within the supply chain and take corrective actions.

c.Inaccurate demand forecasting:

- Effective supply chain management depends on accurate demand forecasting. However, it might be difficult to collect precise data for demand forecasting when there is a lack of collaboration and visibility across stakeholders.

d.Difficulty in meeting surge demands:

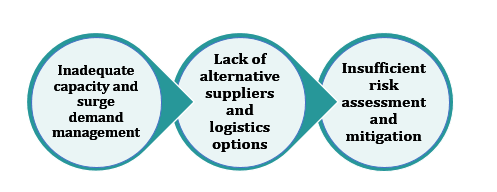

- During emergencies or unexpected events, such as natural disasters or pandemics, healthcare supply chains face sudden surges in demand for specific medical products.

- Without proper coordination and visibility, it becomes challenging to rapidly adjust production, distribution, and inventory management to meet the increased demand.

e.Inefficiencies and delays:

- When there is a lack of coordination and visibility, supply chain processes can become inefficient and prone to delays.

- For example, if healthcare facilities cannot communicate their specific needs accurately, manufacturers may produce and distribute generic or non-essential products instead of prioritizing critical items.

- Fragmented systems: Systems that are not fully integrated or standardised make up the majority of healthcare supply chains. This could result in labor-intensive manual procedures, a reliance on paper-based solutions, and a lack of interoperability between various healthcare organizations. The coordination and flow of information might be hampered by the absence of standardized data formats and communication protocols.

- Lack of contingency planning: Many healthcare facilities and supply chain organisations did not have effective backup plans in place to handle unforeseen disruptions. Failures in the supply chain and challenges in maintaining adequate supplies might result from a lack of readiness for major events or unexpected surges in demand.

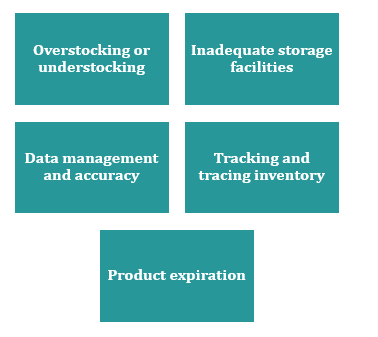

4. Inventory management challenges: Healthcare facilities face challenges in managing their inventory effectively. These challenges include overstocking or understocking essential supplies, inadequate storage facilities, expiration of products, and difficulties in tracking and tracing inventory. Poor inventory management can lead to wastage, increased costs, and delays in accessing critical supplies.

5. Cost pressures: Healthcare facilities often face financial pressures, and supply chain management can become a cost-cutting target. This can result in reduced investment in supply chain infrastructure, inadequate staffing, and limited adoption of technological advancements. Insufficient resources can hamper the efficiency and resilience of the supply chain.

6. Global Supply Chain: Global supply chain disruptions can have a significant impact on the healthcare supply chain, leading to a broken or dysfunctional state.

WAYS TO FIX THE BROKEN SUPPLY CHAIN

- Assess and diagnose the issues:

- To pinpoint the precise locations where the supply chain is faulty or dysfunctional, conduct a detailed analysis of it.

- This may entail gathering information, performing interviews, and outlining the entire procedure.

- You can create focused solutions by comprehending the underlying reasons of the supply chain issues.

- Collaboration and communication should be improved:

- Encourage improved cooperation and communication between supply chain participants.

- This comprises producers, distributors, medical centres, and administrative agencies.

- Create clear avenues for communication, encourage openness, and ease the sharing of information.

- The supply chain’s coordination, responsiveness, and decision-making are all improved by effective collaboration and communication.

- Invest in digitalization and technology:

- Adopt technology to automate and streamline supply chain operations. Implement inventory management software, real-time tracking systems, demand forecasting tools, and supply chain management systems.

- These innovations boost supply chain efficiency, enable data-driven decision-making, and increase visibility.

- Increase resilience by diversifying your sources:

- Find alternative vendors and form reliable alliances. Regularly assess the performance of your suppliers, and have backup plans ready to deal with any disruptions.

- Assessing vulnerabilities, identifying risks, and putting mitigation plans in place are all part of building resilience in the supply chain.

- Improve demand forecasting and planning:

- Enhance your capacity for demand forecasting in order to better predict and satisfy client needs. Utilise past data, market knowledge, and cooperative forecasting with clients and vendors.

- Accurate demand forecasting reduces stockouts, optimises inventory levels, and guards against overstocking.

- Optimize inventory management:

- Improve inventory control by putting in place efficient procedures to avoid shortages, overstocking, and wastage.

- This entails using just-in-time (JIT) or lean inventory management principles, enhancing inventory visibility, maximising stock levels, and putting in place effective stock rotation procedures.

- Boost logistics and transportation:

- Streamline operations to increase effectiveness and cut down on lead times. Utilise technology for route planning and tracking, streamline transportation routes, and enhance delivery timetables.

- Improve warehouse operations through optimising picking and packing procedures, automation, and layout design.

- Set up performance metrics and ongoing development:

- Establish key performance indicators (KPIs) to gauge the effectiveness of your supply chain.

- These metrics should be frequently monitored and used to pinpoint areas that require improvement.

- Apply continuous improvement techniques like Lean Six Sigma approaches to streamline operations, get rid of waste, and boost supply chain effectiveness overall.

- Foster talent development and collaboration:

- Invest in training and development programmes to enhance supply chain expertise within the organisation. Promote talent development and collaboration.

- Encourage exchange of knowledge and cross-functional cooperation. Establish a culture of ongoing learning and development to promote supply chain innovation and adaptation.

- Monitor and adapt to market dynamics:

- Know how the supply chain is affected by market trends, legislative changes, and emerging technology.

- Review and modify supply chain strategy frequently to reflect shifting consumer expectations and market conditions.

CONCLUSION

The healthcare facility’s supply chain is damaged as a result of a number of issues that reduce its efficacy and efficiency. These problems include poor data sharing, fragmented communication, poor inventory management, low visibility, and insufficient contingency planning. These problems result in poor patient care, higher expenses, ineffective resource allocation, and delays in getting necessary medical supplies.

The broken healthcare facility supply chain can be fixed by addressing these problems and putting these ideas into practise, which will increase operational effectiveness, result in cost savings, and improve patient care. A strong supply chain is crucial to ensuring that medical facilities have timely access to the resources they require, which ultimately improves the quality of treatment for all patients.

For in-depth market and financial feasibility studies or any other healthcare-related research needs, please feel free to reach out to us at +91-8655170700 or email us at hospaccx.india@gmail.com . Our team is equipped to provide comprehensive and detailed insights tailored to your specific requirements.