Are you planning to install medical gas pipeline in your hospital? Are you aware of all

the Colour codes for Medical Gas Pipeline System? In this article, Hospaccx Healthcare

Consultancy has mapped all the information related to the colour codes of medical gas

pipeline systems.

INTRODUCTION

Medical gases are used for the patient’s healthcare in different ways. In the early 1950s,

healthcare providers recognized the hazards of using heavy high-pressure cylinders of

medical gases. Instead, the medical gas pipeline system (MGPS) provides medical gases

and vacuum systems. For supplying all these gases to the ultimate point of use, a set of

components and equipment is to be installed. This system starts right from the source

of the gas till the outlet point on the patient’s bed. Combined all such system

components are called MGPS systems.

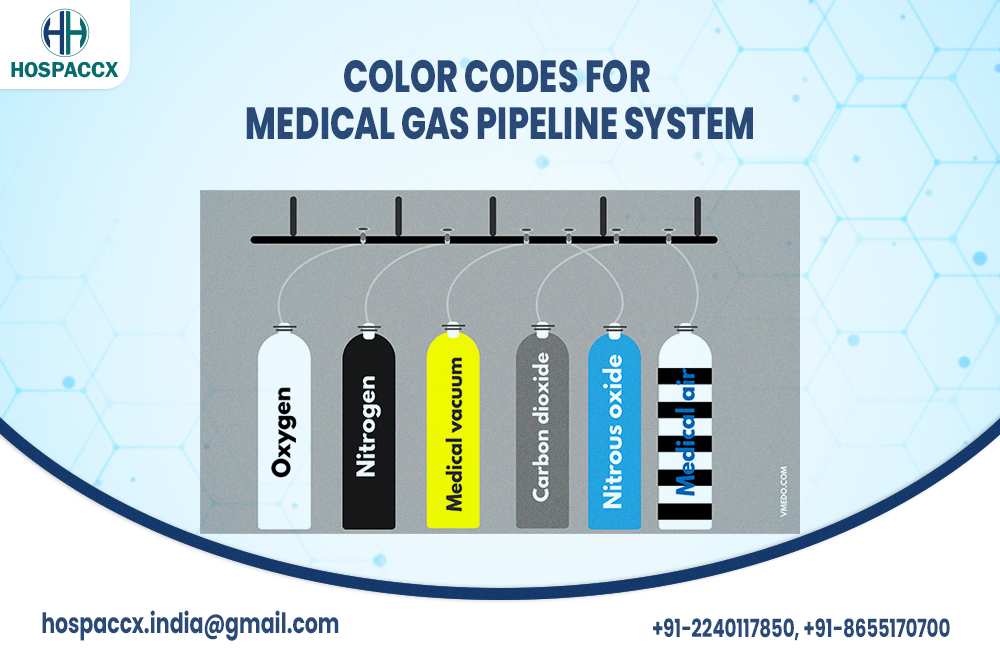

Commonly used medical gases in hospitals are:

● Oxygen

● Nitrous oxide

● Medical air 400 KPa or 4 bar (Ma 4)

● Medical air 700 KPa or 7 bar (MA 7)

● Carbon dioxide

● Oxygen/nitrous oxide mixture [50 %/50 % (by volume)]

● Oxygen-enriched air

● Air for driving surgical tools

● Nitrogen for driving surgical tools

● Vacuum

Each medical gas must be supplied from a separate system. All parts of each system

must be gas specific to ensure that there is no possibility of cross-connection between

systems. Source equipment systems are generally required to be monitored by alarm

systems at the point of supply for abnormal (high or low) gas pressure in areas such as

general wards, operating theatres, intensive care units, recovery rooms, or major

treatment rooms.

INDIAN STANDARD OF COLOUR-CODING FOR MEDICAL GAS PIPELINE SYSTEM

This Indian Standard (First Revision) was adopted by the Bureau of Indian Standards on

27 March 1990, after the draft finalized by the Chemical Engineering Plants and Related

Equipment Sectional Committee had been approved by the Heavy Mechanical

Engineering Division Council.

The FDA’s Compressed Medical Gas Guidelines and Manufacturing Guidelines for

Medical Gases serve as the foremost instruments of patient safety. Because medical

gases can be combustible or act as oxidants. The International standard for the colour

coding of gas pipelines is ISO 32: 1977 Gas pipelines for medical use – Marking for

identification of content. According to the ISO standard, oxygen should be labelled as

white.

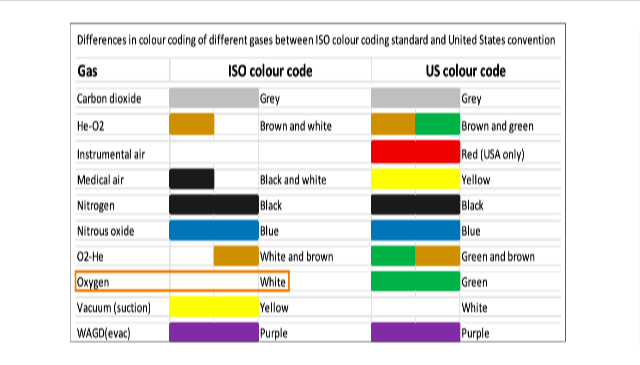

The figure shows differences in gas pipeline colour coding between ISO and US

standards.

BENEFITS OF COLOUR CODING

- Uniformity of colour marking promotes greater safety, lessens the chances of error, and reduces hazards involved in the handling of material inside the pipelines.

- Easy Identification of the particular contents of the pipelines is achieved by imposing suitable colour bands on the ground colour.

- Lettering, as a mode of identification, is also recommended this will reduce the possibility of mistakes in identification.

- There are many gas mixtures used for clinical and medical applications. They are often used for patient diagnostics such as lung function testing or blood gas analysis. Test gases are also used to calibrate and maintain medical devices used for the delivery of anaesthetic gases.

- Whenever the ground colour is not applied throughout the entire length, it shall be applied near valves, junctions, joints, service appliances, bulkheads, walls, etc.

- When colour bands are superimposed on the ground colour, the ground shall extend sufficiently on both sides of the colour bands to avoid confusion.

- Attention shall be given to the visibility of colour marking and the lettering. Where the pipelines are located above the normal line of vision of the operator, the lettering shall be placed below the horizontal line of the pipes.

- Preferably colouring shall be all around the pipe wherever possible, if not, the extent of colouring along the circumferences is to be decided by the purchase Engineer in charge depending upon the direction of visibility at the site.

- BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote the harmonious development of the activities of standardization, marking, and quality certification of goods and attending to connected matters in the Country.

CONCLUSION

Medical gases are nowadays being used for several diverse clinical applications and their piped delivery is a landmark achievement in the field of patient care. Patient safety is of paramount importance in the design, installation, commissioning, and operation of medical gas pipeline systems (MGPS). The system has to be operational round the clock, with practically zero downtime and its failure can be fatal if not restored at the earliest. There is a lack of awareness among clinicians regarding the medico-legal aspect involved with MGPS. It is a highly technical field; hence, in-depth knowledge is a must to ensure safety of the system.

Related Team Members